cnc milling machine parts and their function pdf Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) CNC milling machines are among the most versatile and widely used in the industry. They operate by rotating a cutting tool against a stationary workpiece, allowing for intricate shapes and designs to be crafted with high precision . CNC programming involves you or a fellow colleague using computer-aided manufacturing (CAM) software to convert a CAD file into a language that a CNC machine can read, whether it’s a cutting, milling, or turning tool (although they .

0 · cnc milling programming pdf

1 · cnc milling machine specification

2 · cnc machining handbook pdf

3 · cnc machine tool design pdf

4 · cnc machine manual pdf

5 · cnc machine maintenance manual pdf

6 · cnc machine drawing pdf

7 · cnc machine basic knowledge pdf

Sheet metal stamping involves forming flat sheets of metal into specific shapes, while injection molding uses molten plastic injected into molds. Both processes have their advantages and disadvantages, but one crucial aspect of consideration for any manufacturer is the cost.

cnc milling programming pdf

This manual aims to quickly make you successful in operating the TORMACH CNC Mill and making very precise and high quality parts for your project.

cnc milling machine specification

In CNC machining, there are two primary types of milling machines: the vertical milling machine, with a Bridgeport milling machine being an excellent example, and the horizontal milling machine. Although the milling operations . Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint cutter.The metal removal rate is higher very high as the .

A CNC milling machine has many connected mechanical components which have friction effects such as ball screws and rails. To control servo motors which are used to drive X-Y table in CNC milling .Here’s a closer look at the primary types of CNC machines and their applications. CNC Machining Centers (Milling) CNC milling machines are among the most versatile and widely used in the industry. They operate by rotating a cutting tool against a stationary workpiece, allowing for intricate shapes and designs to be crafted with high precision . A CNC milling machine consists of several key components that work together to precisely machine metal parts.. Spindle. The spindle is the main component that does the cutting. It spins a cutting tool like an end mill, drill, or milling cutter at high speeds, typically ranging from 10,000 to 40,000 revolutions per minute.

CNC manufacturing offers advantages on two types of parts: (1) simple parts that are mass produced and/or (2) complex parts with features requiring multiple axes of simultaneous motion. For simple parts in low quantity, it is often quicker to produce the parts on manual machines (as in lab). • CNC does not inherently imply increased part .

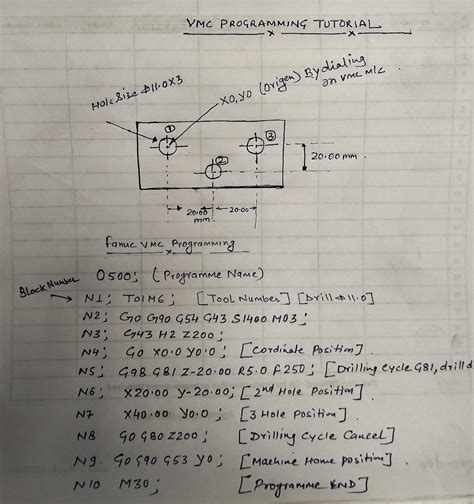

The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.This article highlighted key aspects of milling machines, including their types, functions, and applications. Understanding vertical, horizontal, CNC, and universal milling machines can help optimize production processes. We encourage you to .

cnc machining handbook pdf

cnc machine tool design pdf

weatherproof electrical box with cover

Collectively, these components of a CNC milling machine play a crucial role in achieving precise and efficient machining processes across various industrial applications. We provide a comprehensive CNC milling machine parts list below. CNC Controller. The CNC controller is a vital part of any well-manufactured CNC milling machine.

The document discusses the parts and functions of a lathe machine. It lists 20 main parts including the lead screw, bed, guideways, headstock, spindle, chuck, and tailstock. It describes the purpose and material of each part. It also explains the functions of the lathe machine which include turning, facing, drilling and other operations to remove material and shape workpieces. .

The machine combines the functions of a 3 to 4-axis milling machine and of a 3D printer. . Most of the machine’s parts are manufactured and assembled in the Faculty of Engineering Mechanics .Primary function of the mechanical systems in CNC machines are similar to conventional machines. CNC Lathe machine consists of the following sub systems. 1. Headstock. 2. Axis assembly. 3. Tool post, and 4. Tailstock CNC milling machine consists of following sub systems. 1. Axis assembly. 2. tool magazine, and 3. Bed BEST MAINTENANCE PRACTICES.

CNC milling machine, toolpath, point cloud model, rough machining, finish machining 1 Introduction Toolpath generation is a core task in computer numerical control (CNC) milling machine operations, directly impacting processing quality, efficiency, and tool lifespan (Chen et al., 2021). As a research area with tremendous potential, toolpath .Introduction. 23 Parts of Milling Machine and Their Functions [Complete Guide]: – In a production industry there a heaps of machines tools are available to do an extensive variety of operation in the work piece among them milling machine is one of the machine tool. Interestingly, the most milling machines are controlled by computer programs or algorithms.

These machines differ from column and knee-type milling machines by the construction of their table mounting. The table is mounted directly on the ways of a fixed bed. The table movement is restricted to .• CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces CNC milling machines can produce . A vise with two moveable jaws can hold two parts in one setup. This multi-sided vertical double vise has machinable aluminum jaws, or . The study’s main objective is to propose a process for designing and manufacturing a mini vertical 3-axis CNC milling machine with low cost but full features similar to an industrial CNC machine.

•The most basic function of any CNC machine is automatic, precise, and consistent motion control. •Rather than applying completely mechanical devices to cause motion as is required on most conventional machine tools, CNC machines allow motion control in a revolutionary manner. •All forms of CNC equipment have two or more directions ofCNC Milling Machine. CNC milling is a machining process that uses computerized controls and rotating multipoint cutting tools to produce custom-designed parts or products. These machines operate on three to five axes, creating slots, holes, and details in materials to turn them into vehicles or mechanical parts. The spindle is one of the most important parts of a CNC milling machine that provides power to maneuver and cut material. It consists basically of a rotary shaft, which is driven by an electric motor that rotates at high-speed giving torque for effective interaction with the workpiece. . and bed, explaining their functions and importance in .

Lathe machine ppt - Download as a PDF or view online for free . This document provides information about mechanical engineering and the centre lathe. It discusses the main parts and functions of the lathe, including the headstock, bed, carriage, cross-slide, apron, tailstock, tool post, and quick-change gearbox. . lathe accessories such as .Parts of a CNC Program • Safe-start: clears machine for new operation . • CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces . used for different functions according to their on-screen label. Arrow keys used for constant jogging of . Milling is a versatile process for meeting various manufacturing needs, the machine tool designed for CNC milling is called a milling machine or mill. To produce different features and parts, multiple types of milling machines can be selected. In this article, we’ll introduce a common choice – column and knee type milling machine, and get .

Vertical Milling Machine This study guide will cover the major working parts, functions, and machining techniques that can be found/used on most vertical milling machines. This study guide has been designed to directly represent the questions that will be found on the open book written assessment and as an aid for the hands-on usability assessment.

Some of the CNC machine models are: VMC -640, DX-250, ATM-160, VMC-430, TM-020, AM-430, TMC-350 Given is an example of DX-200 and DX-250. i. Complete CNC machine Dx-200 is completely assembled within 6-7 days, while Dx- 250 takes 8 to 10 days. ii. Minimum rpm is 1 and maximum rpm can be up to 6000. iii.

Cnc Milling - Download as a PDF or view online for free . processes and classifications. It describes the theory of CNC milling machines, including their characteristics, geometry, coordinate systems, zero and reference points, and programming structure. It also covers cutting values, clamping devices, and lists G-codes and M-functions. Read .

cnc machine manual pdf

cnc machine maintenance manual pdf

The junction box master schedule contains the junction box types that could be used by a company in a project. See the Master and Standards Databases section for more information about using master databases. See the Common Schedule Dialog Box Features section for more information about how this dialog box works.I first swapped the outputs of the VPI to see if the buzz changed speakers - it did - telling me it was a turntable issue. The buzz became significantly louder if I touched the head shell screws, and moderately louder if .

cnc milling machine parts and their function pdf|cnc machine drawing pdf